When designing printed circuits for electronic devices, one of the first decisions you’ll need to make is whether to use a single-layer flexible printed circuit (FPC) or a multilayer FPC. Both types of circuits are used in a wide range of electronic applications, but they offer distinct advantages and are suited for different purposes. Understanding the differences between the two will help you make an informed decision based on your specific needs, whether you're developing a consumer electronics product, a medical device, or any other high-tech system.

In this article, we’ll compare single-layer and multilayer FPCs, examining their features, benefits, and limitations. We’ll also explore the factors you should consider when choosing the right type of FPC for your project, ensuring that your design is both functional and cost-effective.

What is a Single-Layer FPC?

A single-layer FPC, also known as a single-sided flexible printed circuit, is one of the most basic types of flexible printed circuits. It consists of a single layer of conductive material (typically copper) that is laminated onto a flexible substrate, such as polyimide or PET (Polyethylene Terephthalate). The conductive traces are etched onto this copper layer to form the circuit pattern. Single-layer FPCs are usually used for relatively simple designs with lower-density circuitry.

Features of Single-Layer FPC:

One Conductive Layer: Only one layer of copper is used to create the circuit, making it relatively simple and cost-effective to produce.

Cost-Effective: The manufacturing process is simpler, which makes single-layer FPCs more affordable compared to multilayer alternatives.

Flexibility: Single-layer FPCs are highly flexible, which makes them ideal for applications where the circuit needs to be bent, folded, or twisted.

Low Density: These FPCs are typically used for low-density applications where fewer components need to be interconnected.

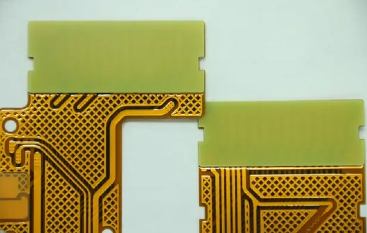

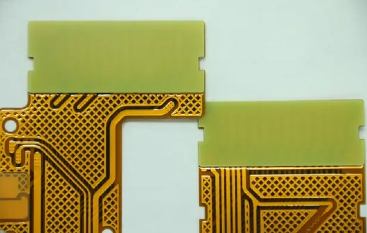

What is a Multilayer FPC?

A multilayer FPC, as the name suggests, is made up of multiple layers of conductive material (usually copper) separated by insulating layers. These layers are stacked on top of each other and bonded together using an adhesive or other bonding materials. Multilayer FPCs can have three or more layers, with some designs having up to 12 layers or more. The increased number of layers allows for higher-density circuit designs, which are crucial in applications that require complex interconnections or compact layouts.

Features of Multilayer FPC:

Multiple Layers of Conductive Material: Multilayer FPCs have several layers of copper that are used to create more intricate and dense circuits.

Compact Design: Because of the multiple layers, multilayer FPCs can integrate more components in a smaller space, which is ideal for space-constrained applications.

Higher Density Circuits: The added layers allow for more complex interconnections and smaller vias, enabling high-density circuit designs.

Increased Performance: The additional layers provide improved signal integrity, reduced electromagnetic interference (EMI), and better thermal management.

Durability: Multilayer FPCs tend to be more robust and durable, capable of handling higher electrical and mechanical stresses.

Key Differences Between Single-Layer FPC and Multilayer FPC

When deciding between a single-layer FPC and a multilayer FPC, several factors come into play, such as cost, performance requirements, and the complexity of the design. Below, we’ll compare the two types of FPCs across several key dimensions.

1. Design Complexity and Flexibility

Single-Layer FPC:

Simple design with one conductive layer.

Best suited for applications with less complex circuits and fewer components.

Extremely flexible, which is advantageous in products that need to bend or flex frequently.

Multilayer FPC:

More complex design with multiple layers of conductive traces.

Suitable for high-density designs with numerous components or intricate connections.

While multilayer FPCs are still flexible, they tend to be less flexible than single-layer FPCs due to the additional layers and materials.

2. Cost and Manufacturing Complexity

Single-Layer FPC:

Lower cost due to simpler manufacturing processes.

Easier and quicker to produce because of the single layer structure.

Ideal for cost-sensitive projects or products with low complexity.

Multilayer FPC:

Higher cost due to the additional layers, more complex manufacturing, and the need for precise alignment and bonding.

The production process is more intricate, requiring additional steps such as drilling vias and electroless copper plating.

Best suited for high-end applications where performance is critical and cost is secondary.

3. Space Efficiency and Compactness

Single-Layer FPC:

Ideal for applications where space is not a major concern.

Limited in the number of components that can be integrated on a single layer, which means the design will require more space for the same number of components compared to a multilayer FPC.

Multilayer FPC:

Highly space-efficient, allowing for the integration of many components in a compact design.

Multilayer FPCs are ideal for miniaturized electronics, such as wearables, mobile devices, and other small form-factor products that require high-density circuits.

4. Electrical and Signal Performance

Single-Layer FPC:

Adequate for low-frequency and simple applications but may not offer optimal performance in high-speed or high-frequency circuits.

Limited shielding capabilities, making it more prone to electromagnetic interference (EMI) and signal degradation over longer distances.

Multilayer FPC:

Superior electrical performance due to better shielding and the ability to reduce signal interference.

Ideal for high-frequency applications or those requiring low signal loss and stable signal integrity.

Multilayer FPCs provide better routing options and can isolate sensitive signals more effectively, reducing the risk of noise and crosstalk between traces.

5. Durability and Mechanical Stress Resistance

Single-Layer FPC:

Suitable for applications with lower mechanical stress, such as consumer electronics or simple control systems.

Less durable than multilayer FPCs in harsh environments or high-stress conditions.

Multilayer FPC:

More robust and durable due to the additional layers that provide structural support and resistance to mechanical stresses.

Suitable for high-stress applications, such as automotive electronics, industrial systems, and aerospace components.

6. Applications and Use Cases

Single-Layer FPC:

Best suited for simple electronic applications, such as basic mobile devices, remote controls, LED displays, and wearable gadgets that do not require high-density circuitry.

Often used in situations where flexibility and ease of integration into a compact form factor are prioritized.

Multilayer FPC:

Used in more advanced electronic systems requiring high-density interconnections, such as smartphones, tablets, laptops, medical devices, automotive electronics, and military equipment.

Also used in high-speed applications like 5G communication, where signal integrity and minimal interference are critical.

Factors to Consider When Choosing Between Single-Layer and Multilayer FPC

When deciding which type of FPC is right for your project, there are several key factors to consider:

Circuit Complexity: If your project involves a simple circuit with limited components, a single-layer FPC may suffice. However, for complex designs with multiple components, a multilayer FPC is necessary to maintain performance and space efficiency.

Cost Constraints: Single-layer FPCs are more cost-effective and are ideal for budget-conscious projects. Multilayer FPCs, while more expensive, are justified when high-density, high-performance circuits are needed.

Performance Requirements: For applications requiring high-speed signals, low noise, and minimal interference, multilayer FPCs offer superior performance. Single-layer FPCs may be more appropriate for simpler, lower-performance applications.

Space Limitations: If your project has strict space constraints and requires a high number of components to be packed into a small area, a multilayer FPC will be more efficient.

Environmental and Mechanical Considerations: Consider the mechanical stress your FPC will be subjected to. Multilayer FPCs tend to be more durable and resistant to damage from bending, vibration, and other stresses.

Conclusion

Choosing between a single-layer FPC and a multilayer FPC ultimately depends on the complexity, performance requirements, cost considerations, and space limitations of your project. Single-layer FPCs offer a cost-effective, simple solution for less demanding applications, while multilayer FPCs are better suited for advanced designs that require high-density interconnections, superior performance, and durability.

By understanding the differences between the two types of FPCs and considering the specific needs of your application, you can make an informed decision that ensures the best results for your project.

For high-quality and reliable FPC solutions, whether single-layer or multilayer, HECTACH offers expert manufacturing capabilities to meet the needs of any electronic design. With a focus on precision, performance, and cost-effectiveness, HECTACH provides custom FPC solutions for a wide range of industries, from consumer electronics to automotive and medical devices.