Introduction

Choosing the right PCB (Printed Circuit Board) for your project is crucial to ensure optimal performance and cost-effectiveness. Both Rigid PCB vs. Flexible PCB are popular in the electronics industry, each with distinct advantages. In this article, we will explore the key differences between Rigid PCB vs. Flexible PCB, helping you determine which is best for your needs based on their features and benefits.

Understanding Rigid PCBs

What is a Rigid PCB?

A rigid PCB is a solid and inflexible board typically made from fiberglass (FR4) and epoxy resin. These boards provide structural support for electronic components and maintain their shape throughout the lifespan of the device. Rigid PCBs are essential for devices that require stability and high component density, such as desktop computers and industrial machinery.

Key Benefits of Rigid PCBs

Rigid PCBs offer several advantages for electronic designs. They are cost-effective, especially for mass production, and provide mechanical stability, making them ideal for static applications. Their structure supports high-density component placement, ensuring efficient use of space. Additionally, the standard manufacturing processes for rigid PCBs are well-established, leading to lower production costs.

Common Applications of Rigid PCBs

Rigid PCBs are widely used across various industries, from consumer electronics to medical devices. The table below outlines their common applications, technical specifications, and key considerations to help guide your decision-making process.

| Application Area | Device Examples | Technical Specifications | Considerations |

| Consumer Electronics | Televisions, Desktop Computers | High component density, thermal stability up to 130°C, can support multi-layer designs (up to 30+ layers) | Must be designed for static use, not suitable for bending or movement |

| Automotive Systems | Control Modules, Infotainment Systems | High vibration resistance, temperature tolerance up to 125°C, supports dense circuits | Needs robust design to endure vibrations and temperature fluctuations |

| Industrial Equipment | Machinery, Robotics, Industrial Controllers | Can support large components, thermal dissipation up to 150°C, multi-layer options for complex circuits | Ensure durability under mechanical stress, often requires complex assembly |

| Medical Devices | Diagnostic Machines, Medical Monitors | Stability under constant use, high-frequency performance, can support heavy components | Requires high reliability and low failure rates, often in stationary environments |

| Other High-End Equipment | Aerospace Components, Military Systems | Can handle extreme temperatures, electromagnetic interference shielding, often multi-layered designs | Used in harsh environments requiring high signal integrity and durability |

Tip:When selecting a rigid PCB, ensure the thermal stability and mechanical strength meet the requirements of the application, especially in environments with high vibrations or temperature fluctuations.

Exploring Flexible PCBs

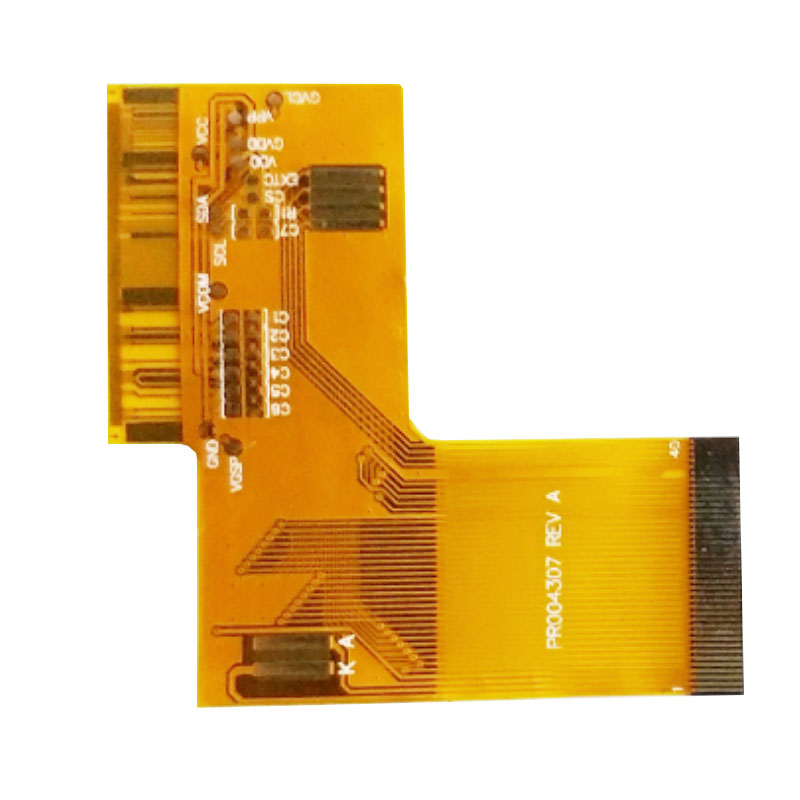

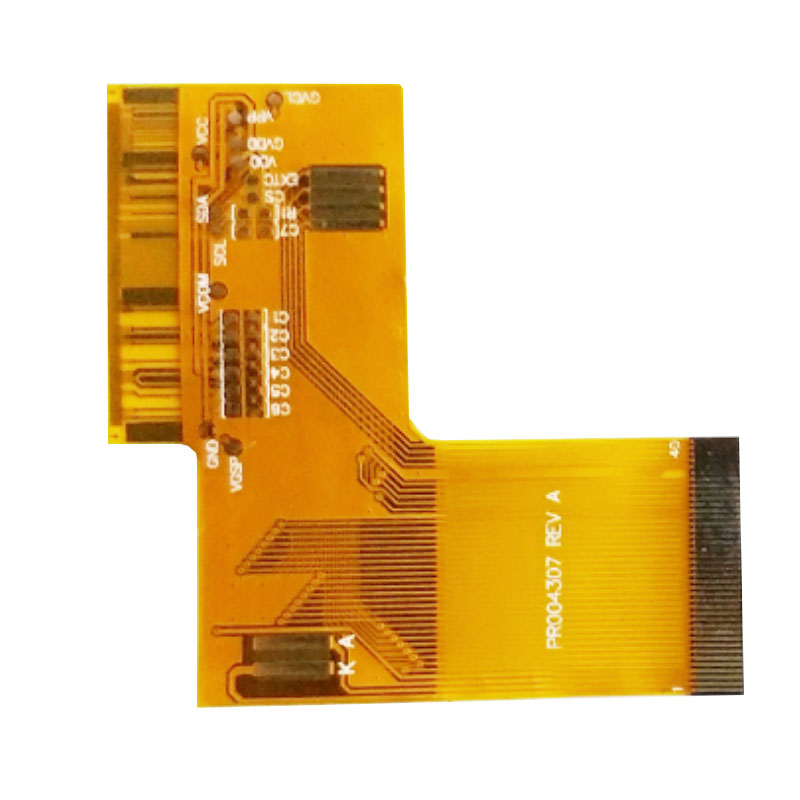

What is a Flexible PCB?

Flexible PCBs are made from thin, bendable materials such as polyimide. These boards can bend, twist, and fold, making them ideal for applications requiring dynamic flexibility or compact designs. Flexible PCBs are commonly used in modern devices that need to fit into tight spaces or endure motion, such as wearables and medical implants.

Key Benefits of Flexible PCBs

Flexible PCBs provide excellent space efficiency and are significantly lighter than rigid PCBs. They can be molded into 3D shapes, allowing for more compact and complex designs. Their flexibility makes them highly durable in environments with vibrations or frequent movement. These characteristics are particularly beneficial in dynamic applications where rigidity is a disadvantage.

Common Applications of Flexible PCBs

Flexible PCBs play a crucial role in various high-tech devices, particularly in wearables, medical devices, and automotive systems. The following table outlines their applications, technical specifications, and key considerations to help you understand their practical use in design.

| Application Area | Device Examples | Technical Specifications | Considerations |

| Wearable Electronics | Smartwatches, Fitness Trackers | Low weight, thickness as thin as 0.1mm, bending radius at least 10x the material thickness | Ensure reliable connections in bending areas, avoid damage |

| Medical Devices | Pacemakers, Catheters, Sensors | Flexible design, high temperature resistance, vibration resistance, commonly made from polyimide (PI) | Requires additional protection for long-term durability |

| Automotive Systems | Automotive Sensors, Dashboard Displays | High temperature tolerance, vibration-resistant design, operating temperature up to 150°C+ | Environmental factors impact performance, high reliability required |

| Consumer Electronics | Smartphones, Cameras | Lightweight design, space-saving, thickness typically 0.2mm-0.5mm | Must address electromagnetic interference and thermal management |

| Other High-Tech Devices | Drones, Satellite Communication Equipment | High signal integrity, low interference, frequency up to several GHz | Ensure solid connections and high-frequency signal transmission quality |

Rigid-Flex PCBs: Combining the Best of Both Worlds

What is a Rigid-Flex PCB?

Rigid-flex PCBs integrate both rigid and flexible sections within a single board, offering the best of both worlds. They are particularly advantageous in applications where traditional rigid boards lack the required flexibility, or flexible PCBs cannot provide the necessary structural support. Rigid-flex designs combine the mechanical strength of rigid boards with the adaptability of flexible circuits, making them ideal for compact, high-performance devices like medical implants, aerospace components, and automotive sensors.

Benefits of Rigid-Flex PCBs

Rigid-flex PCBs save space by eliminating the need for connectors and cables, making them ideal for compact applications. They offer improved reliability by reducing the number of potential failure points (such as connectors) and enabling better signal integrity. These boards are often used in high-performance applications like aerospace and medical devices where both rigidity and flexibility are needed.

Key Considerations for Using Rigid-Flex PCBs

The complexity of rigid-flex PCBs can present challenges during design and manufacturing. The integration of both rigid and flexible components requires careful planning, especially in managing thermal and mechanical stresses across different sections. Special considerations must also be given to the transition between rigid and flexible parts to avoid potential signal integrity issues. While they increase design time and cost, the advantages of increased reliability, space-saving, and performance make them worthwhile for applications in high-reliability environments.

Key Differences Between Rigid and Flexible PCBs

Material and Structure

Rigid PCBs are made from materials like fiberglass (FR4), providing a sturdy, inflexible structure that can support heavy components. Flexible PCBs, on the other hand, are constructed from polyimide, which allows them to bend and conform to different shapes. The difference in materials affects both manufacturing processes and design possibilities, with flexible PCBs offering more versatility in terms of shape and size.

Cost and Manufacturing

Rigid PCBs are generally more affordable to produce due to the established manufacturing processes and materials used. They are well-suited for large-scale production runs, resulting in lower costs per unit. Flexible PCBs, however, require specialized materials and more complex manufacturing techniques, which can drive up costs, particularly for multi-layer designs.

Performance and Durability

Rigid PCBs provide high mechanical stability, making them ideal for stationary applications. They are reliable in environments that do not involve movement or vibration. Flexible PCBs, conversely, excel in dynamic environments where movement or vibration is present. Their ability to withstand bending, folding, and vibration makes them more durable in certain applications, but they are not as robust in static environments.

How to Decide Between Rigid and Flexible PCBs

Cost vs. Function

The decision between rigid and flexible PCBs often boils down to balancing cost and functionality. If your design is static and cost is a primary concern, rigid PCBs are the more economical option. However, if flexibility and compact design are more important, and budget permits, flexible PCBs offer significant advantages in terms of space-saving and adaptability.

Space and Design Constraints

For devices with strict space constraints, flexible PCBs are ideal because they can be molded into compact shapes that rigid PCBs cannot achieve. If your design requires a more straightforward, stable structure, rigid PCBs are better suited. Flexible PCBs can save significant space, but at the cost of a more complex design process.

Environmental and Durability Needs

Flexible PCBs are best suited for dynamic environments where the device will experience movement, vibration, or harsh conditions. In contrast, rigid PCBs are better for stable, static environments where durability is needed without the need for movement. The choice depends largely on the operating conditions of the device.

Comparing Performance in Various Industries

Electronics and Consumer Goods

Rigid PCBs are the go-to choice for most consumer electronics due to their affordability and reliability in stable applications. Flexible PCBs, however, are preferred for compact and dynamic devices, such as wearables, where their lightweight and adaptability provide a significant edge.

Medical Devices

In the medical field, flexible PCBs are often used for devices that require compact, bendable designs, such as pacemakers and diagnostic tools. Rigid PCBs, however, are found in medical equipment that needs to withstand long-term use in stable environments, like imaging devices.

Automotive and Aerospace

Rigid-flex PCBs are commonly used in aerospace and automotive applications where both flexibility and stability are necessary. These environments often require both high reliability and the ability to fit complex shapes, making rigid-flex PCBs the ideal choice for such demanding sectors.

Design Tips for Optimizing PCB Performance

Plan Your Layer Stack-Up Early

When designing rigid or flexible PCBs, early planning of the layer stack-up is critical for managing impedance and ensuring optimal signal integrity. Carefully choose materials and layer arrangements to minimize cross-talk and signal loss, particularly in high-frequency applications. For high-speed designs, use controlled impedance layers and plan via locations to prevent signal degradation. Advanced techniques like microvia designs and differential pair routing can further enhance performance, especially for high-speed digital circuits.

Minimize Bending Stress in Flex Designs

In flexible PCB design, minimizing bending stress is vital to prevent early failure. Ensure the bending radius is significantly larger than the PCB thickness, typically 10-15 times the material thickness, to prevent damage to the traces and vias. The coverlay should also be carefully selected for flexibility and protection, reducing the risk of cracking. To extend the lifespan of flexible PCBs, use reinforcement in areas subjected to frequent movement, such as joint locations, to preserve their mechanical integrity.

Test Signal Integrity

Simulating signal integrity is an essential step in PCB design, especially for high-speed applications. For both rigid and flexible PCBs, simulate the high-frequency behavior to identify and mitigate potential signal loss and reflection. In rigid-flex PCBs, the transition between rigid and flexible sections must be carefully analyzed for impedance mismatch, which can cause performance degradation. Utilize tools like 3D EM simulation software to predict and address issues such as crosstalk and return loss before manufacturing to ensure reliable performance.

Conclusion

When choosing between Rigid PCB vs. Flexible PCB, it's essential to evaluate your project's specific requirements. Rigid PCBs provide durability and cost-effectiveness for static applications, while Flexible PCBs excel in dynamic, compact designs. For projects needing both flexibility and rigidity, Rigid-Flex PCBs offer an ideal hybrid solution, though at a higher cost. Consider space, cost, and durability to make the best choice for your needs. HECTACH offers high-quality PCB solutions, ensuring that your design is both reliable and efficient, meeting the unique demands of your project.

FAQ

Q: What is the difference between Rigid PCB vs. Flexible PCB?

A: Rigid PCBs are inflexible and provide structural support for heavy components, while Flexible PCBs are made from bendable materials, offering flexibility and compact design options for dynamic applications.

Q: When should I choose Rigid PCB vs. Flexible PCB?

A: Choose Rigid PCBs for stability, cost-effectiveness, and high-density applications, while Flexible PCBs are ideal for applications needing space-saving, adaptability, and durability in dynamic environments.

Q: Are Rigid PCB vs. Flexible PCB more expensive?

A: Rigid PCBs are typically more affordable to produce due to simpler manufacturing processes, while Flexible PCBs are more expensive due to advanced materials and complex production techniques.

Q: Can Rigid PCB vs. Flexible PCB be used in medical devices?

A: Yes, both types can be used in medical devices. Rigid PCBs are common in stable equipment, while Flexible PCBs are preferred for compact, wearable medical devices.