Flexible Printed Circuits (FPC) have become a cornerstone in modern electronics, offering lightweight, reliable, and space-efficient solutions for a wide range of applications. Among the different types of FPC, multilayer FPC stands out due to its ability to integrate multiple conductive layers within a flexible structure. This unique combination allows for more complex and compact designs while maintaining the high performance required by many industries. In this article, we will delve into what multilayer FPC is, its advantages, and the various applications it serves in today’s rapidly evolving tech landscape.

What is Multilayer FPC?

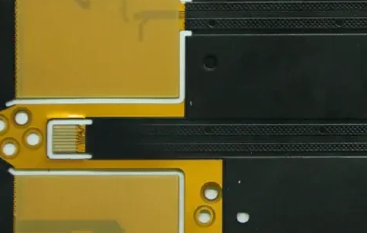

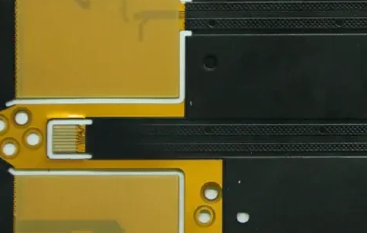

A multilayer FPC refers to a flexible printed circuit board (PCB) that contains more than one conductive layer of circuitry, stacked together and laminated for increased density and complexity. Unlike traditional single-layer FPCs that have only one conductive trace layer, multilayer FPCs incorporate several layers, typically ranging from two to many more, depending on the design requirements. The layers are bonded together with an insulating material, often using high heat and pressure, to form a flexible, compact circuit board.

The conductive layers in multilayer FPCs are interconnected through plated-through holes (PTH) or via connections. This configuration allows for complex, high-density interconnections within a minimal footprint, making multilayer FPCs a preferred choice for modern electronic devices.

Advantages of Multilayer FPC

1. Space Efficiency

One of the primary advantages of multilayer FPCs is their ability to save space. With multiple conductive layers stacked within a single structure, they allow for compact circuit designs. This space-saving feature is particularly important in industries such as consumer electronics, automotive, and medical devices, where space is often limited. By reducing the need for larger circuit boards and simplifying the design, multilayer FPCs contribute to the miniaturization of modern devices.

This efficiency is not just about saving physical space but also about optimizing the layout of circuits. More layers allow for more complex circuit designs, meaning that more functions can be integrated into a smaller, thinner product.

2. Improved Signal Integrity

In electronics, signal integrity refers to the quality and reliability of the electrical signals transmitted through a circuit. Multilayer FPCs offer improved signal integrity compared to single-layer FPCs due to their ability to better control the path of the signal through dedicated layers.

The internal layers can act as a shield, reducing interference from external sources and minimizing signal degradation. By optimizing the placement of different circuit traces, multilayer FPCs help maintain the purity of signals, which is crucial for high-speed and high-frequency applications, such as telecommunications and data transmission.

3. Increased Durability

Multilayer FPCs tend to be more durable than their single-layer counterparts. This is primarily because they are made of robust materials, such as polyimide, which can withstand harsh environments, including high temperatures, humidity, and mechanical stress. The multi-layered structure adds an extra level of protection, helping prevent damage to the delicate circuitry inside the device.

Additionally, the flexible nature of FPCs allows them to be bent, folded, or twisted without compromising their functionality. This flexibility is essential for applications in portable electronics, wearables, and devices that require flexibility in their design, such as flexible displays.

4. Enhanced Design Flexibility

Another major advantage of multilayer FPCs is the flexibility they offer in terms of design. With multiple layers, designers can create more intricate circuit layouts and integrate additional components within the same space. This capability allows for the development of more sophisticated devices with improved performance, all while maintaining a compact and lightweight form.

Moreover, multilayer FPCs can be designed to accommodate specific functions such as power distribution, signal routing, and shielding all within a single flexible package. This versatility enables manufacturers to create custom solutions that meet the unique requirements of their products.

5. Reduced Interference and Crosstalk

Crosstalk and electromagnetic interference (EMI) are common issues in electronic circuits, particularly in high-density designs. The layered construction of multilayer FPCs provides built-in shielding between layers, reducing the likelihood of interference between the various circuits. By isolating sensitive signal paths and providing grounding layers, multilayer FPCs minimize noise and signal disruption, making them ideal for applications that require high precision and performance.

6. Cost-Effectiveness for Complex Designs

Although the initial cost of manufacturing a multilayer FPC may be higher than that of a single-layer FPC, the overall cost-effectiveness becomes apparent in more complex designs. The ability to integrate multiple functions into a single flexible circuit board reduces the need for additional components, interconnections, and additional circuit boards, which can ultimately lead to cost savings in the production process.

By reducing the number of parts and assembly steps, multilayer FPCs also help streamline the manufacturing process, making them an attractive choice for companies looking to optimize both design and production costs.

Applications of Multilayer FPC

Multilayer FPCs are widely used across various industries due to their versatility, compactness, and high performance. Below are some of the most prominent sectors where multilayer FPCs are making a significant impact:

1. Consumer Electronics

Consumer electronics are among the largest consumers of multilayer FPC technology. Devices like smartphones, tablets, laptops, smartwatches, and cameras all rely on FPCs for their internal circuits. The growing demand for thinner, more compact devices has made multilayer FPCs essential in creating products with multiple functions within a limited space.

In smartphones, for example, multilayer FPCs are used to connect components such as the screen, camera, sensors, and buttons, all while keeping the device slim and lightweight. The flexible nature of FPCs also allows for creative designs, such as foldable smartphones.

2. Automotive Industry

As vehicles become more technologically advanced, the demand for high-performance and durable electronic systems increases. Multilayer FPCs are used in automotive electronics, including infotainment systems, navigation units, advanced driver assistance systems (ADAS), and lighting systems.

In vehicles, FPCs can be used to connect components in areas with limited space, such as dashboard circuits or door panels. Their flexibility allows them to be integrated into curved or irregularly shaped spaces, making them ideal for automotive applications that require both flexibility and durability.

3. Medical Devices

The medical industry has seen a growing adoption of flexible and compact electronic components, particularly in wearable medical devices, diagnostic equipment, and implantable systems. Multilayer FPCs are used in a variety of medical applications, including heart monitors, hearing aids, glucose monitoring devices, and more.

Because these devices often require small form factors and the ability to withstand challenging environments, multilayer FPCs are an ideal solution. Their flexibility ensures that medical devices can conform to the shape of the body, and their durability ensures reliable performance over time, even in harsh conditions.

4. Telecommunications

Telecommunication devices, such as routers, switches, and antennas, benefit from the use of multilayer FPCs due to their high-speed data transmission capabilities and compact design. These devices need to handle large amounts of data and operate in environments where space is limited, making multilayer FPCs an excellent choice.

In the case of antennas, multilayer FPCs can be designed to include both the circuitry and antenna within the same flexible structure, further optimizing space and performance.

5. Wearable Technology

The rise of wearable devices, such as fitness trackers, smartwatches, and health monitoring gadgets, has driven demand for smaller and more efficient electronic components. Multilayer FPCs are ideal for these applications due to their compact size, flexibility, and ability to integrate multiple layers of circuitry.

Wearables require a high degree of miniaturization, and multilayer FPCs allow manufacturers to create smaller, more efficient devices without compromising performance. They also provide the durability necessary for devices that must withstand constant movement and exposure to the elements.

6. Aerospace and Defense

In the aerospace and defense industries, where reliability and performance are paramount, multilayer FPCs are used in avionics, navigation systems, and communication devices. These systems often operate in extreme conditions, requiring components that are both durable and lightweight. The flexibility of multilayer FPCs allows them to be used in confined spaces, while their durability ensures long-term performance in challenging environments.

Conclusion

Multilayer FPCs have revolutionized the way modern electronics are designed and manufactured, offering numerous advantages over traditional rigid PCBs. Their space-saving design, enhanced signal integrity, flexibility, and ability to handle complex circuits make them a critical component in a wide range of industries, from consumer electronics to medical devices, automotive systems, and beyond.

As technology continues to advance and demand for smaller, more powerful devices increases, multilayer FPCs will continue to play a vital role in shaping the future of electronics. Their ability to integrate multiple functions in a compact, flexible, and durable design ensures they will remain a top choice for manufacturers seeking high-performance solutions.

With the ongoing development of materials and manufacturing techniques, multilayer FPC technology is poised for even greater innovations. As we look ahead, these versatile and reliable circuits will remain at the forefront of electronic design, enabling the next generation of smarter, more efficient devices.