Introduction

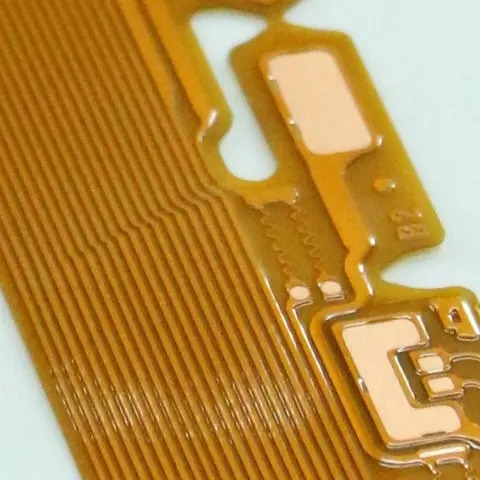

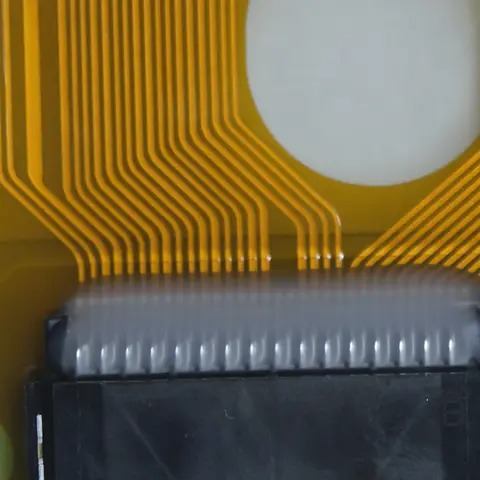

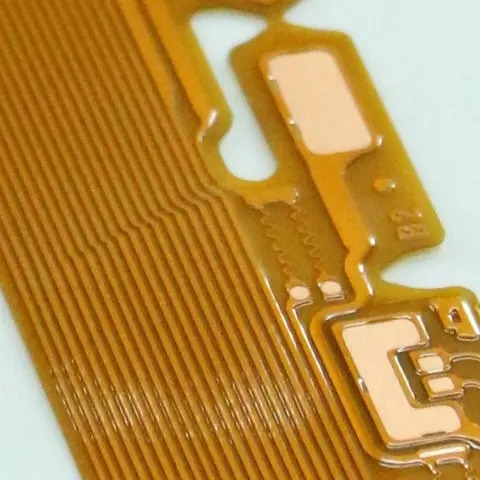

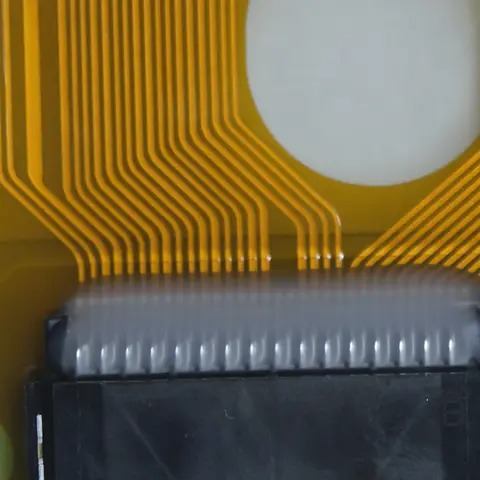

Flexible printed circuit boards (FPCs) have transformed electronics by offering compact, lightweight, and adaptable solutions. They bend, twist, or flex to fit tight spaces while maintaining electrical function. In this article, we’ll explore the primary materials used in flexible PCBs, such as polyimide (PI), polyester (PET), and liquid crystal polymer (LCP). You’ll learn how these materials impact the performance, flexibility, and durability of FPCs.

Understanding Flexible PCBs

What are Flexible PCBs?

Flexible PCBs are a type of electronic circuit designed to be flexible. Unlike traditional rigid boards, flexible PCBs use thin, flexible substrates that allow them to bend and conform to a variety of shapes without compromising electrical functionality. These boards typically consist of a conductive copper layer, an insulating substrate, and an adhesive layer to bond the components together. Flexible PCBs are used in applications where space, weight, and flexibility are critical, such as wearable devices, automotive systems, and portable electronics.

Key Applications of Flexible PCBs

Flexible PCBs are essential in industries where compact, lightweight designs are a priority. In consumer electronics, they can be found in smartphones, tablets, and wearable devices, where they allow for thinner and more flexible designs. In the automotive industry, flexible PCBs are used in safety systems, sensors, and lighting. They are also critical in medical devices, such as pacemakers and hearing aids, where flexibility is required to fit in constrained spaces. Aerospace applications also rely on flexible PCBs for their ability to withstand extreme conditions while maintaining high performance.

| Industry | Applications | Key Considerations | Technical Specifications |

| Consumer Electronics | Smartphones, tablets, wearable devices | Thin, flexible designs for compact devices | Flexibility: High; Temperature Resistance: 150°C to 200°C; Signal Integrity: High |

| Automotive | Safety systems, sensors, lighting, engine control units | Must withstand vibrations and high temperatures | Thermal Resistance: 200°C+; Durability: High; Flexibility: Medium |

| Medical Devices | Pacemakers, hearing aids, medical monitoring devices | Must fit in constrained spaces and withstand body temperatures | Flexibility: High; Biocompatibility: Essential; Temperature Resistance: 37°C to 50°C |

| Aerospace | Flight control systems, satellite communication, navigation equipment | Ability to withstand extreme environmental conditions | Temperature Resistance: 300°C+; Chemical Resistance: Excellent; Flexibility: High |

Tip: When selecting flexible PCBs for high-performance industries such as aerospace or medical devices, prioritize materials with higher temperature and chemical resistance, as they ensure long-term reliability and durability under extreme conditions.

Why Material Choice is Crucial

The material used in a flexible PCB plays a pivotal role in determining its performance, durability, and adaptability. Materials such as polyimide (PI) offer high thermal resistance and mechanical strength, making them suitable for high-performance applications. In contrast, polyester (PET) provides a cost-effective solution for low-demand applications but offers limited heat resistance. The choice of material directly impacts factors such as heat tolerance, flexibility, signal integrity, and the overall lifespan of the flexible PCB.

The Primary Substrate Material: Polyimide (PI)

Polyimide Properties and Benefits

Polyimide is the most commonly used substrate for flexible PCBs due to its exceptional thermal stability, flexibility, and electrical properties. It can withstand temperatures exceeding 260°C, making it ideal for applications that involve high heat. Polyimide also has a low dielectric constant, which minimizes signal loss in high-frequency circuits. Its flexibility allows it to endure repeated bending without cracking, making it a preferred choice for dynamic flex applications in demanding environments.

Common Applications of Polyimide-Based FPCs

Polyimide-based FPCs are widely used in industries such as aerospace, automotive, and medical devices, where reliability and high performance are critical. In aerospace, polyimide FPCs are used in flight control systems, satellite communications, and navigation equipment. In automotive systems, they are found in safety systems like airbags, sensors, and engine control units. Polyimide's durability and thermal stability make it the material of choice for these high-performance applications.

| Industry | Applications | Key Considerations | Technical Specifications |

| Aerospace | Flight control systems, satellite communications, navigation equipment | Requires high thermal stability and resistance to extreme environments | Temperature Resistance: 300°C+; Durability: High; Signal Integrity: Excellent |

| Automotive | Airbags, sensors, engine control units | Must withstand vibrations, high temperatures, and mechanical stress | Temperature Resistance: 200°C+; Vibration Resistance: High; Flexibility: Medium |

| Medical Devices | Pacemakers, hearing aids, medical monitoring devices | Must be biocompatible and able to endure continuous use in varying conditions | Temperature Resistance: 37°C to 50°C; Flexibility: High; Durability: High |

| High-Performance Systems | Used in critical circuits requiring reliability and thermal stability | Long-term reliability in dynamic environments | Thermal Stability: Excellent; Flexibility: High; Durability: Superior |

Polyimide’s Cost vs. Performance Tradeoff

Polyimide is a premium material, and while it offers superior thermal and mechanical properties, it comes with a higher cost compared to alternatives like polyester (PET). The cost of polyimide-based FPCs is justified in applications where performance, durability, and high temperature resistance are essential. For less demanding applications, polyester can be a more economical choice, but it compromises on thermal and mechanical properties.

Polyester (PET) as an Alternative Substrate

Properties of Polyester in Flexible PCB Design

Polyester (PET) is a more affordable alternative to polyimide, offering adequate flexibility and performance for less demanding applications. It is lighter and thinner than polyimide, making it suitable for consumer electronics that do not require high heat resistance. PET’s dielectric properties are also suitable for low-frequency applications. However, its thermal resistance is limited, typically to around 150°C, which makes it unsuitable for high-temperature applications.

Limitations of Polyester in Harsh Environments

While polyester is cost-effective and suitable for low-demand applications, its limited thermal resistance restricts its use in environments with high heat. In applications like automotive or industrial systems, where temperatures can exceed PET’s threshold, polyimide or LCP would be more appropriate. Polyester also lacks the mechanical durability of polyimide, which is crucial for applications involving repeated flexing or bending.

Ideal Use Cases for Polyester-Based FPCs

Polyester-based flexible PCBs are an excellent choice for cost-sensitive applications, where the performance requirements are less demanding. These include low-power devices such as calculators, basic displays, and toys. Polyester offers good flexibility and moderate electrical insulation but lacks the high thermal and mechanical properties needed for high-performance environments. It is ideal for applications that do not involve high-frequency signals or excessive heat generation. By choosing polyester, manufacturers can achieve significant cost savings while maintaining adequate performance for non-critical applications, making it a practical solution for mass-market products.

Emerging Materials: Liquid Crystal Polymer (LCP)

LCP’s High-Frequency Performance Advantages

Liquid Crystal Polymer (LCP) is increasingly being used as a substrate material for high-speed and RF circuits due to its excellent high-frequency performance. LCP offers a dielectric constant of 2.85 at 1 GHz, making it ideal for high-frequency digital circuits where minimal signal loss is essential. LCP’s stability and low moisture absorption also make it highly suitable for environments with fluctuating temperatures and humidity.

Durability and Moisture Resistance of LCP

One of the key advantages of LCP over polyimide is its low moisture absorption rate, which is only 0.04%. This makes LCP highly resistant to environmental factors like humidity, which can affect the performance of other materials like polyimide and polyester. LCP’s moisture resistance and dimensional stability make it ideal for high-performance applications that require long-term reliability.

Cost and Application Considerations for LCP

While LCP offers superior performance in terms of moisture resistance, high-frequency stability, and durability, it comes at a higher cost than both polyimide and polyester. This makes it a more suitable option for high-performance applications, such as RF circuits, mobile communications, and aerospace. Engineers must carefully consider the trade-off between cost and performance when selecting LCP for a given application.

| Industry | Applications | Key Considerations | Technical Specifications |

| RF Circuits | High-frequency applications, mobile communications, antennas | High-frequency stability and low signal loss are critical | Dielectric Constant (Dk): 2.85 at 1 GHz; Moisture Absorption: 0.04% |

| Mobile Communications | Wireless communication devices, smartphones, and tablets | High performance required under varying environmental conditions | Temperature Resistance: 260°C+; Mechanical Strength: High; Moisture Resistance: Excellent |

| Aerospace | Satellite systems, flight control systems, GPS | Must perform under extreme environmental conditions | Thermal Stability: 300°C+; Flexibility: High; Chemical Resistance: Superior |

| High-Speed Digital Circuits | Used in high-speed processing and signal transmission devices | Minimal moisture absorption and low thermal expansion | Thermal Expansion: Low; Signal Integrity: Excellent; High Frequency Performance: Superior |

Tip: For high-performance applications such as RF circuits and aerospace, LCP is the ideal choice due to its superior moisture resistance, high-frequency stability, and durability. However, its higher cost means it should be selected only when performance demands justify the expense.

Conductive Layer: Copper Foil

Copper Foil Types: Rolled vs. Electrolytic

There are two primary types of copper foil used in flexible PCBs: rolled copper foil and electrolytic copper foil. Rolled copper foil is highly flexible, making it suitable for dynamic flex applications. Its structure is more ductile, which allows it to withstand repeated bending. Electrolytic copper foil, on the other hand, is used for applications requiring finer lines and higher density, as it provides a smoother surface for precise etching.

Role of Copper in Conductivity and Reliability

Copper is the most common conductive material used in flexible PCBs. It forms the circuit traces that carry electrical signals across the board. Copper’s excellent conductivity ensures minimal resistance, which is essential for high-speed circuits. It also plays a critical role in ensuring the reliability of flexible PCBs by providing a stable and consistent electrical pathway.

Choosing the Right Copper Thickness for FPCs

The thickness of the copper foil used in a flexible PCB depends on the current-carrying requirements of the application. Thicker copper is necessary for high-current applications to reduce the risk of overheating, while thinner copper is more suitable for low-power devices. Copper foil thickness ranges from 12 μm to 35 μm, with options for rolled or electrolytic copper depending on the specific needs of the PCB.

The Importance of Adhesives in Flexible PCBs

Types of Adhesives Used in FPC Construction

Adhesives play a crucial role in bonding the layers of a flexible PCB, ensuring structural integrity during bending and flexing. Common adhesives used in FPC construction include epoxy, acrylic, and modified epoxy resins. These adhesives are chosen based on their ability to withstand temperature fluctuations and mechanical stress while maintaining a strong bond between the layers.

| Adhesive Type | Properties | Advantages | Common Applications |

| Epoxy | High strength, temperature resistance, good adhesion properties | Strong bonding, excellent chemical and heat resistance | Used in high-temperature applications and rigid-flex PCBs |

| Acrylic | Good flexibility, fast curing time, low viscosity | Quick bonding, good performance at moderate temperatures | Ideal for applications with moderate mechanical stress |

| Modified Epoxy | Enhanced flexibility, better bonding with different substrates | Combines high strength with increased flexibility | Used in flexible PCBs that require both strength and flexibility |

Adhesive Properties That Impact Flexibility

The adhesive used in flexible PCBs must possess certain properties to maintain the board’s flexibility. It should exhibit high elasticity and be resistant to thermal cycling, ensuring that the PCB can withstand repeated bending without delaminating. Adhesives with high tensile strength are often selected to ensure that the PCB can handle mechanical stress without compromising performance.

Standards for Adhesive Selection in Flexible Circuits

Standards such as IPC-6013D provide guidelines for adhesive selection in flexible circuits. These standards ensure that the adhesives used meet the necessary requirements for bonding strength, thermal resistance, and flexibility. Engineers must adhere to these standards to ensure that the flexible PCB can endure the stresses encountered during manufacturing and operation.

Coverlay Films: Protecting the PCB

Materials Used for Coverlay Films

Coverlay films are crucial for ensuring the long-term functionality of flexible PCBs. Polyimide (PI) and polyester (PET) are the two most commonly used materials. PI is often preferred for high-performance applications due to its excellent heat resistance and mechanical strength, making it suitable for environments that involve high temperatures and mechanical stress. On the other hand, PET is a more affordable alternative, offering adequate protection in lower-cost, less demanding applications where extreme conditions are not a factor.

Functions of Coverlay Films

Coverlay films act as a protective layer, shielding the delicate conductive traces from environmental elements such as dust, moisture, and chemicals. They also prevent physical damage to the PCB during flexing, which is critical for ensuring the durability of flexible circuits. In addition to providing electrical insulation, coverlay films help maintain the structural integrity of the PCB by enhancing its resistance to repeated bending and mechanical stress, thus prolonging its lifespan in dynamic applications.

Selection Criteria for Coverlay Thickness and Materials

When selecting coverlay materials and thickness, engineers must evaluate factors such as operating temperature, environmental exposure, and the level of mechanical flexibility required for the application. Thicker coverlay films provide better protection, especially in harsh environments, but may decrease flexibility, which is essential for dynamic flex applications. Engineers must balance the trade-off between sufficient protection and maintaining the flexibility necessary for reliable performance, ensuring the material is suited for both protection and operational demands.

Best Practices for Material Selection in Flexible PCBs

Matching Material Properties with Application Requirements

Selecting the right material for a flexible PCB starts with understanding the application requirements. Factors such as temperature resistance, flexibility, and environmental exposure must be considered. Polyimide is ideal for high-performance applications, while polyester is a good option for low-cost, low-demand applications. LCP is suitable for high-frequency circuits, but its higher cost must be justified by the performance needs.

The Role of Industry Standards in Material Selection

Industry standards like IPC-6013D provide engineers with the necessary guidelines for material selection, testing, and performance criteria. Adhering to these standards ensures that the materials used in flexible PCBs meet the required specifications for durability, heat resistance, and electrical performance. Following these standards helps maintain product reliability and longevity.

Considerations for Cost-Effective and Reliable FPC Designs

When designing flexible PCBs, engineers must balance material costs with performance requirements. While high-performance materials like polyimide and LCP provide superior functionality, they come at a higher cost. Polyester and other materials offer more affordable options for less demanding applications. Engineers should weigh the long-term benefits of material performance against the initial cost to achieve a cost-effective and reliable design.

Conclusion

The primary materials used in flexible PCBs, such as polyimide, polyester, and LCP, significantly impact the performance, flexibility, and durability of the circuits. HECTACH offers high-quality polyimide-based flexible PCBs, ideal for applications requiring superior thermal and mechanical properties. For less demanding applications, HECTACH also provides polyester-based solutions, ensuring cost-effectiveness without compromising reliability. Whether for high-frequency circuits or high-performance systems, HECTACH’s diverse range of flexible PCBs meets various industry needs, ensuring optimal value and performance.

FAQ

Q: What is the primary material of a Flexible PCB?

A: The primary materials used in a Flexible PCB are polyimide (PI), polyester (PET), and liquid crystal polymer (LCP), each offering unique properties like flexibility, thermal resistance, and signal integrity.

Q: Why is polyimide commonly used in Flexible PCBs?

A: Polyimide is favored for its superior thermal stability, flexibility, and electrical properties, making it ideal for high-performance applications in industries like aerospace and automotive.

Q: How does polyester compare to polyimide in Flexible PCB applications?

A: Polyester is a more cost-effective alternative to polyimide, offering adequate performance for low-demand applications but lacking the thermal resistance required for high-performance environments.

Q: What are the advantages of using LCP in Flexible PCBs?

A: LCP offers excellent high-frequency performance, moisture resistance, and durability, making it suitable for RF circuits, mobile communications, and aerospace applications.

Q: How do I choose the right material for my Flexible PCB?

A: Choose based on application needs: Polyimide for high performance, polyester for cost-effectiveness, and LCP for high-frequency circuits. Each material impacts flexibility, heat resistance, and signal integrity.